Linerless printers – a smart step towards a greener and more efficient industry

Linerless Labeling: What Is It and Why Is It the Future?

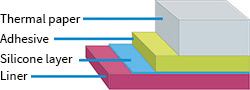

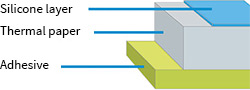

Linerless – or liner-free – labels have become an essential part of many companies’ sustainability strategies. These labels do not require a removable backing liner, which means less waste, a reduced CO₂ footprint, and lower storage and transportation costs. The adhesive side of the label is ready for immediate application, making them suitable for direct printing and application onto packaging.

The importance of linerless technology is also emphasized by the European Union and other major economies aiming to achieve a carbon-neutral, non-toxic, and fully circular economy by 2050. Linerless solutions enable businesses to contribute to these goals today.

Why Choose a Linerless Solution?

1. Ecological and Economic Benefits

By implementing linerless printers, businesses can achieve:

Up to 40% more labels per roll – resulting in fewer roll changes and less downtime.

Less waste – up to 50% less waste compared to traditional labels.

Lower CO₂ emissions – with reductions of up to 50%.

Reduced raw material use – more labels from fewer resources.

Example: In 2022, the shipment volume for the top U.S. courier companies (UPS, FedEx, USPS) was estimated at $215.5 billion – a sector where label waste is a major environmental issue. Linerless labels offer a clear alternative.

2. Efficiency and Reliability

Linerless labels bring multiple benefits across manufacturing and logistics chains:

Fast and uninterrupted labeling thanks to longer rolls.

Flexibility – labels of different lengths can be printed from the same roll.

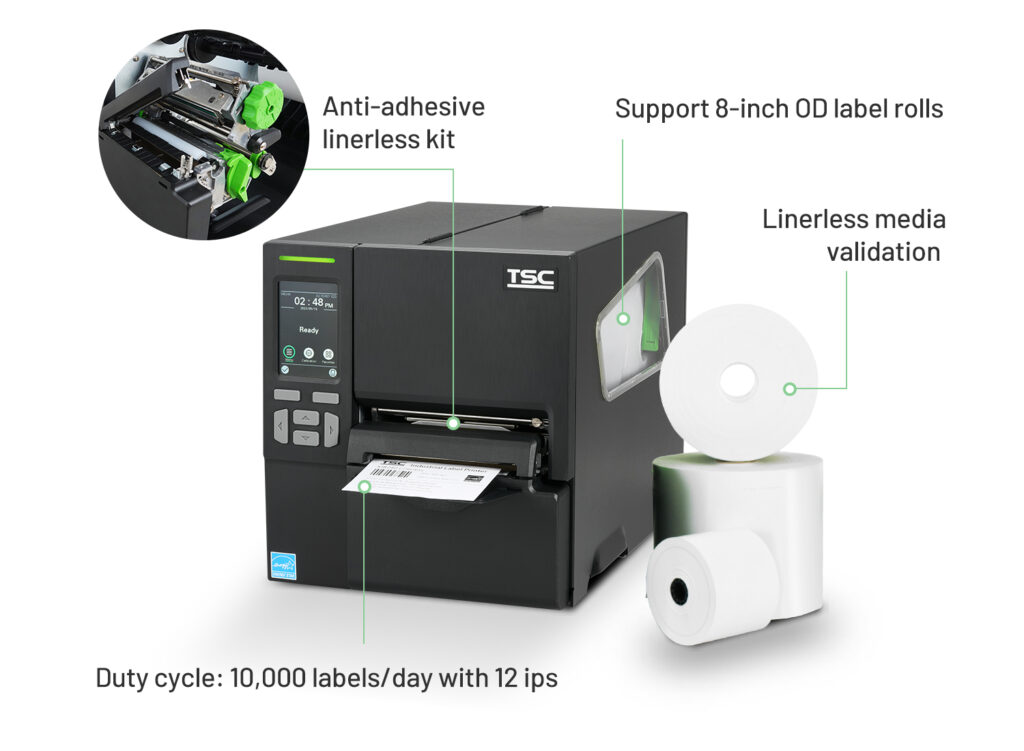

For example, the TSC MB240 linerless printer:

Can process up to 10,000 labels per day.

Offers a print speed of up to 12 inches per second (30.5 cm/s) for high-throughput tasks.

Supports large rolls (up to 203 mm in diameter), reducing the need for roll changes.

Is tested with leading linerless label brands, including both permanent and removable adhesives.

Complete Systems: Cab HERMES QL and InNo-Liner Solutions

Cab HERMES QL Systems

Cab offers fully automated HERMES QL print-and-apply systems using direct thermal printing. These systems are:

Maintenance-free (no ribbon required),

Eco-friendly (no liner waste),

Suitable for various industrial and logistics applications.

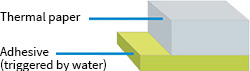

InNo-Liner Technology

In collaboration with HERMA, Cab has developed the InNo-Liner system, where the adhesive is only activated upon contact with water. This makes the labels completely free of silicone and liner backing, making them especially suitable for absorbent surfaces such as cardboard and paper. Ideal for:

Logistics centers and shipping labels,

Environments that demand fast, automated, and precise label application.

Who Are Linerless Printers For?

Logistics and Warehousing: Fast labeling, reduced waste, lower costs.

Retail: Price tags, promotional labels, packaging identification.

Healthcare: Precise labeling for tubes and pharmaceuticals.

Food Industry: BPA-free labels, safe for food contact.

Linerless – A Sustainable Investment

Linerless labels and printers aren’t just new technology — they are a response to the growing demand for environmentally friendly, cost-efficient, and reliable solutions. Want to reduce expenses, boost productivity, and meet green transition goals? Then it’s time to consider linerless technology.