LINK360

One of the biggest challenges in maintaining workplace safety is information management. “Lockout and tagout” procedures, maintenance schedules for equipment, and other necessary documents need constant updating and review.

LINK360 clearly shows when and which equipment needs maintenance, and how to do it, while being flexible enough to suit both small manufacturing facilities and large international companies. Although saving lives cannot be given a price, more than 500,000 procedures created with Brady LINK360 have nonetheless helped save $100 million and over 300,000 work hours worldwide.

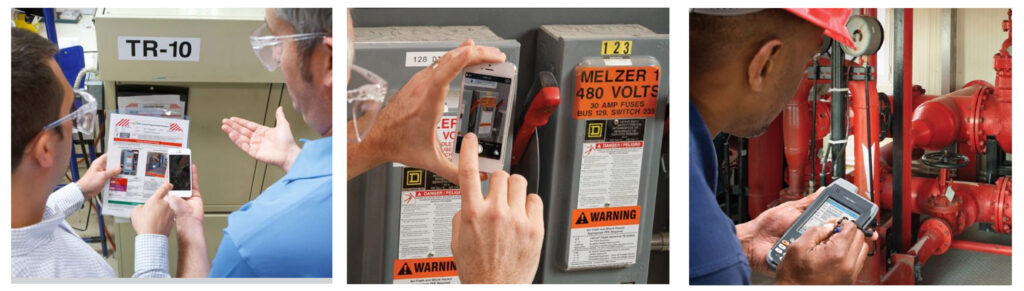

Of course, safety cannot be ensured by sitting behind a desk; action is required on-site. The advantage of LINK360 is its mobile apps, which give you the freedom to manage lockout procedures from a smart device, from quickly creating procedures with photos taken on your phone to sharing and approving them.

LINK360 is convenient:

- You can see what and when you need to maintain.

- You can follow step-by-step instructions with images on how to maintain the equipment so nothing is missed.

- If you need to take a break, you can pick up where you left off.

- The system automatically generates a report of the completed tasks. A short overview is provided in the video:

If there are only a few pieces of equipment, specialized software might not always be necessary; for example, Excel might suffice. But with more equipment, tracking maintenance becomes more complex. LINK360 consolidates all information into one place and reminds you when it’s time to inspect a piece of equipment. This way, you can be sure that all the equipment in use is safe and regularly maintained. Another advantage of LINK360 is its convenience and simplicity: the software asks the necessary questions to create procedures and adds pictures as well. Additionally, LINK360 is always accessible from anywhere—all you need is a web browser and an internet connection.