The most common mistake when setting up a printer!

The most common mistake, that clients can make, is not using the correct combination of material and ribbon!

“Are you using the right ribbon with your material?” This is the number one question we ask from our clients, when they say that the printer is not printing correctly or there is some kind of problem with the print durability or the quality.

What can happen, if you combine the wrong ribbon and material?

It can result in poor printing quality and durability, such as smudging, fading or illegibility. It can also damage your printer and lead to increased maintenance costs.

Important things to remember when choosing a ribbon for your material.

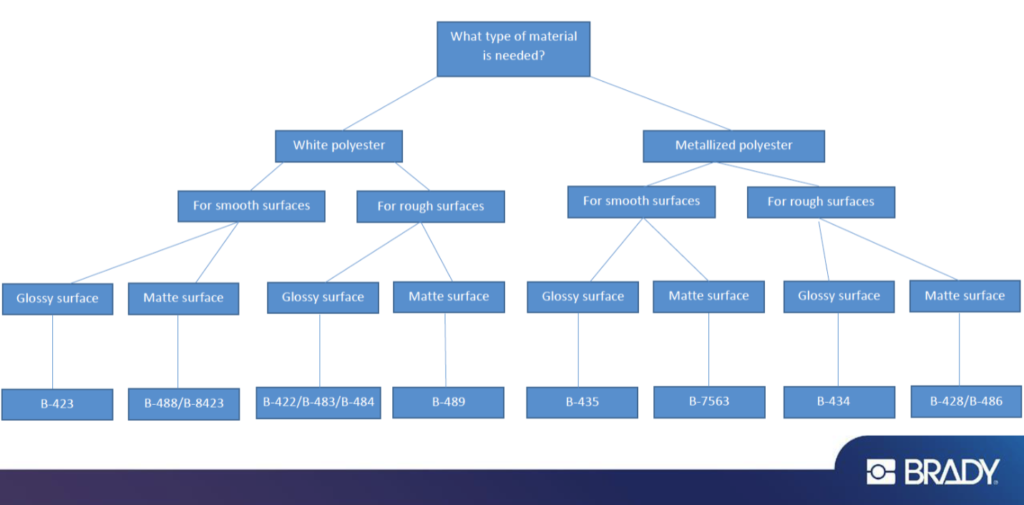

To ensure that the material can withstand the environment, it is very important that the correct combination of material and ribbon is used:

- Glossy and hard materials need ribbons containing resin. The resin melts at higher temperatures which is needed to allow for the ink to stick/burn into the material topcoat

- Matte and porouse materials need ribbons containing both resin and wax. The wax helps filling the uneven surface and gives good print quality. Melts at lower temperatures

Also, 5 things you need to take under consideration while picking a ribbon:

1. Ribbon Type and Wind Direction

2. Ribbon Size

3. Ribbon Material

4. Ribbon Quantity

5. Ribbon/Printer compatibility

So if you have any problem picking the right ribbon with your material, then ask our sales representatives for the best solutions.

Ps! Also Bradys smart-cell printers remove the risk of using the wrong combination of material and ribbon!